-

Home

-

Us

- Application Industry

-

Sort

- Sanitary pipe fittings

- Clamp Pipe joint Stainless steel blind plate

- Tee Elbow Reducer

- Quick-release female thread male thread leather hose connector

- Stainless steel head cleaning ball

- Pipe support

- Quick-release joint Quick-release joint sight glass

- Sanitary sealing Series

- Manhole seal

- Quick-release pipe joint gasket

- Union gasket

- Butterfly valve seal

- Flange gasket

- Other gaskets

- Sanitary valve series

- Sanitary quick-install butterfly valve

- Sanitary ball valve

- Check valve Diaphragm valve Angle seat valve

- Respirator Filter Safety Valve

- Industrial field

- FlangSeries

- Valve fittings series

- Valve Series

-

Shop

- Sanitary rubber gasket series

- Manway seal-Shop

- Quick-release pipe joint gasket-Shop

- Union gasket-Shop

- Butterfly valve seal-Shop

- Flange gasket-Shop

- Other gaskets-Shop

-

Blog

-

Contact

-

Home

-

Us

- Application Industry

-

Sort

- Sanitary pipe fittings

- Clamp Pipe joint Stainless steel blind plate

- Tee Elbow Reducer

- Quick-release female thread male thread leather hose connector

- Stainless steel head cleaning ball

- Pipe support

- Quick-release joint Quick-release joint sight glass

- Sanitary sealing Series

- Manhole seal

- Quick-release pipe joint gasket

- Union gasket

- Butterfly valve seal

- Flange gasket

- Other gaskets

- Sanitary valve series

- Sanitary quick-install butterfly valve

- Sanitary ball valve

- Check valve Diaphragm valve Angle seat valve

- Respirator Filter Safety Valve

- Industrial field

- FlangSeries

- Valve fittings series

- Valve Series

-

Shop

- Sanitary rubber gasket series

- Manway seal-Shop

- Quick-release pipe joint gasket-Shop

- Union gasket-Shop

- Butterfly valve seal-Shop

- Flange gasket-Shop

- Other gaskets-Shop

-

Blog

-

Contact

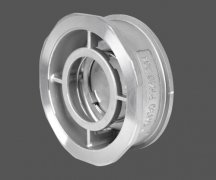

Stainless Steel Wafer Check Valve (H71W)

Stainless Steel Wafer Check Valve (H71W)

Brand: JINOU

Category: stainless steel valve

Name: Wafer check valve (H71W) Process: Silica sol precision casting Size: 1/2-6(DN15-DN150) Standard: ASME B16.34 Pressure: PN1.6MPa, 150LB, 10K, 16K Material: 304\304L, 316\316L...

| Name: | wafer check valve (H71W) |

| Process: | Silica Sol Precision Casting |

| Size: | 1/2 "-6"(DN15-DN150) |

| Standard: | ASME B16.34 |

| Pressure: | PN1.6MPa, 150LB, 10K, 16K |

| Material: | 304\304L, 316\316L |

Stainless Steel Wafer Check Valve (H71W)

The Stainless Steel Wafer Check Valve (H71W) is a vital component in industrial pipelines that ensures the smooth and efficient flow of fluids while preventing backflow. This type of valve is widely used in various industries, including oil and gas, chemical, water treatment, and power generation.

One of the key features of the H71W valve is its construction using high-quality stainless steel. Stainless steel is known for its excellent corrosion resistance, making it ideal for applications where the valve is exposed to harsh environments or corrosive fluids. This material ensures the longevity and reliability of the valve, reducing the need for frequent maintenance and replacement.

The wafer design of the H71W valve allows for easy installation and space-saving. It is designed to fit between two flanges, eliminating the need for additional pipe fittings. This design not only saves installation time but also reduces the overall cost of the system. The compact size of the valve makes it suitable for applications where space is limited, without compromising its performance.

The check valve mechanism of the H71W ensures that fluid flows in one direction only, preventing backflow and potential damage to the pipeline system. The valve opens automatically when the pressure on the inlet side exceeds the pressure on the outlet side. Once the pressure equalizes, the valve closes, preventing any reverse flow. This mechanism is crucial in maintaining the efficiency and integrity of the system.

The H71W valve is also equipped with a spring-loaded disc, which provides a quick response and reliable sealing. The disc is designed to prevent leakage, even in high-pressure applications. This feature ensures that the valve remains tight and efficient, minimizing any loss of fluid or pressure.

In addition to its functionality, the H71W valve is designed with safety in mind. It complies with international standards and undergoes rigorous testing to ensure its reliability and performance. The valve is also equipped with various accessories, such as limit switches or position indicators, which allow for remote monitoring and control.

In conclusion, the Stainless Steel Wafer Check Valve (H71W) is an essential component in industrial pipelines. Its high-quality stainless steel construction, compact design, and reliable check valve mechanism make it a preferred choice for various industries. With its durability, efficiency, and safety features, the H71W valve ensures the smooth and uninterrupted flow of fluids, contributing to the overall efficiency and productivity of the system.

Sort:

Industrial field: