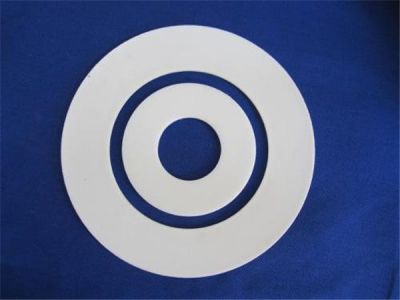

Flange Gasket PTFE Gasket

-

Flange Gasket: PTFE Gasket

Flange gaskets play a crucial role in ensuring a tight seal between two connecting flanges in various industrial applications. Among the different types of flange gaskets available, the PTFE gasket stands out for its exceptional properties and versatility.

PTFE, or polytetrafluoroethylene, is a synthetic fluoropolymer of tetrafluoroethylene. It is widely recognized for its excellent chemical resistance, low coefficient of friction, and high-temperature resistance. These properties make PTFE gaskets highly suitable for use in industries such as chemical processing, oil and gas, pharmaceuticals, food processing, and many others.

One of the key advantages of PTFE gaskets is their superior chemical resistance. They can withstand exposure to a wide range of corrosive chemicals, acids, and bases without deteriorating. This property ensures that the gasket maintains its integrity over time, preventing leakages and ensuring a reliable seal.

Another notable feature of PTFE gaskets is their low coefficient of friction. This characteristic reduces the amount of torque required during installation, making it easier and quicker to assemble flanged connections. The low friction also minimizes the risk of damage to the gasket, ensuring its longevity.

PTFE gaskets are also known for their excellent temperature resistance. They can withstand extreme temperatures ranging from -200°C to +260°C (-328°F to +500°F) without losing their sealing properties. This makes them suitable for applications that involve both cryogenic and high-temperature environments.

Furthermore, PTFE gaskets exhibit excellent electrical insulation properties, making them ideal for use in electrical applications. They are non-conductive and can effectively isolate electrical components, thereby preventing the risk of short circuits and electrical failures.

In addition to their exceptional physical properties, PTFE gaskets are also highly versatile. They can be manufactured in various shapes and sizes to suit different flange configurations. This flexibility allows for easy installation and compatibility with a wide range of flange designs.

In conclusion, PTFE gaskets are a reliable choice for ensuring a tight seal between flanges in industrial applications. Their exceptional chemical resistance, low coefficient of friction, high-temperature resistance, and electrical insulation properties make them highly suitable for use in various industries. With their versatility and durability, PTFE gaskets continue to be a popular choice for sealing flanged connections.

-

Commodity Details:

-

Manufacturer JINOU

-

Specifications 61*107

-

Thickness 3

-

Ltem No. Teflon Gasket

-

Processing customization is

-

Use temperature 260

-

Use pressure 63

-

Is standard

-

Is imported No

-

Is cross-border source No

-

Scope of application Pump

-

Special properties of corrosion resistance

-

Shape flat type

-

Model DN50

-

Samples or spot

-

Function fixed seal

-

Commonly used PTFE gasket classification: PTFE gasket, modified PTFE gasket, expanded PTFE gasket

-

Teflon gasket is also called PTFE gasket or Teflon (Teflon) gasket. Flat gaskets, V-shaped gaskets, piston rings, ball valve gaskets, etc. made of PTFE rods, tubes and plates by mechanical turning or cutting can also be molded into molded Teflon gaskets by mold compression molding and high temperature vulcanization.

-

PTFE has excellent corrosion resistance, aging resistance, insulation, cleanliness and other good characteristics, so it is widely used in chemical, petroleum, pharmaceutical, food and many other fields, known as the "plastic king". PTFE has good corrosion resistance, PTFE does not absorb water, is not affected by oxygen, UV weather resistance is good. Because PTFE is prone to cold flow and creep under pressure and high temperature, it is very suitable for sealing parts with strong corrosion or no contamination at low pressure, low temperature or medium temperature. PTFE has good mechanical strength can be processed into different shapes of PTFE products, and can also be used in combination with other materials, such as PTFE coated gaskets, wound gaskets, or as a layer of metal gaskets.

-

Note: PTFE gasket will become brittle when the temperature is lower than -185 * C, and will creep crack when it is higher than 200 * C, so it should not be used at too high temperature. PTFE gasket has low thermal conductivity and large linear expansion coefficient. Cold flow phenomenon will occur under load. Therefore, it is recommended to use it on medium temperature and low pressure concave and convex surface, full plane and groove flange.

-

PTFE:

-

1, High temperature resistance-the use of working temperature of 250 * C

-

2, Low temperature resistance-has good mechanical toughness; even if the temperature drops to -180 * C, it can maintain 5% elongation.

-

3, Corrosion resistance-for most chemicals and solvents, showing inert, strong acid and alkali, water and various organic solvents.

-

4, Weather-resistant-have good aging life in plastics.

-

5, High lubrication-is the low coefficient of friction in solid materials.

-

6, No adhesion-solid materials in the surface tension is small, do not adhere to any substance.

-

Choose Our Four Reasons:

1, good faith business, reasonable price, quality assurance

2, source direct supply sales model, sufficient supply, high cost performance

3, technical support, engineers to answer all kinds of technical questions for you

4, perennial spot sales, no time limit

-